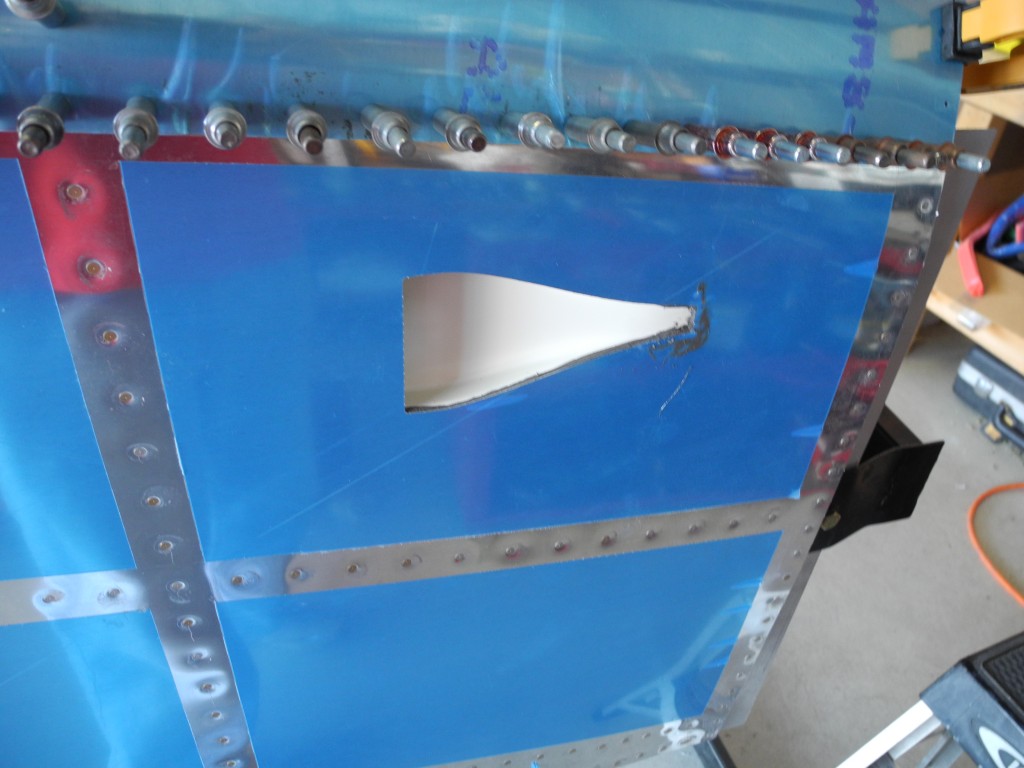

This has been a BIG week-end for us. We have finally built a stand to allow us to attach the motor mount, wings and landing gear. The fuselage stand was a re-purposed stand we had used before the rotisserie, and part of the wing stand. Here is a BIG hint: never throw out old lumber. You will be needing it again. Here is what the new stand looks like:

Also, for the first time, we were able to sit in the fuse and make airplane noises! Wow. I still have chills!

For folks building an experimental, sitting in it for the first time is a big deal. I finally know how I will fit while flying. I fit pretty well. I need to lease a few pounds tho. *sigh*

Where do we stand? Wings and done, Tail is done, flight surfaces are done, Instrument panel frame is done. Radios are mounted but not wired. Ready for motor mount, tail and wing install.

We are staring to wind down on the riveting, and I think I’ll miss that. To see the process, check out:

Riveting Wings on You Tube

We have the motor to install, lots of wire, and now all we need is the time.

More Later.