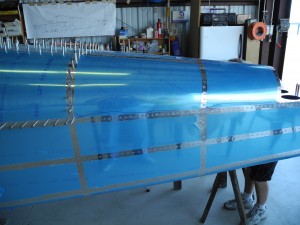

Finally! It is starting to look more like a plane than a canoe. *sigh* Lots of small stuff and you see no change. Do a little BIG stuff and it looks like real progress. So, top skin is on, and parking brake valve is back.

Fuselage under construction

We had a visit from the man who will be giving us the pink slip tonight. I wanted him to see how we are working, and get an idea what to expect when we are done.

I think it is VERY worthwhile to have professional eyes have a look at the project every once in awhile. We have an A&P/IA wander by. The local EAA guru has been by, and now the future DAR has had a look. We do careful work, but extra looks are always welcome.

When getting advice from more than professionals (friends, relatives, other builders, etc.) it is a good idea to listen and evaluate. There are a ton of OWT, SB, and OCITIHIOTI out there that will need to be evaluated. Always look for stuff in writing before you believe everything you hear.

OWT: Old wives Tales

SB: Superstitious behavior

OCITIHIOTI: “Of course it’s true, I heard it on the Internet”

Dkb