No, I’m not talking about me. I’m good at riveting, but rather a pretty cool tool I discovered at Harbor Freight.

On the Van’s Airforce and other Van’s aircraft lists, there is considerable discussion about which rivet gun should I buy? 2X? 3X? These things are pretty expensive, and you want to be sure you get the right one first!

Well, not so! Enter the 1X gun from autoparts stores, hardware chains or (best of all) Harbor Freight!

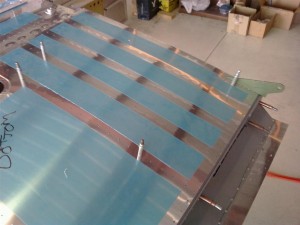

HB and others sell a small, lightweight Air Hammer for under $10 (yes, I said ten dollars) that is GREAT for AN426AD3-x rivets, especially the TONS of rivets that you do on the wings.

You have to get the right one, and with just a little careful selection, you can have GREAT looking skin! I’ve just finished my wings, and they look GREAT!

What is the difference between an Air Hammer and a Rivet gun? About $150.00

What to look for?

1. Small and light. Better control and you won’t tire after 500 rivets or so.

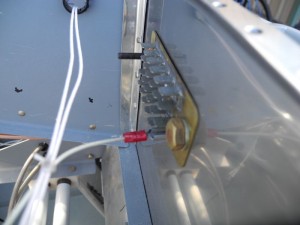

2. A trigger you can feather, like this one.

Trigger you can feather

This was not so good a choice:

Trigger with poor feather control

3. Built-in regulator. This worked VERY nice:

Pressure regulator on Air Hammer

4. Throw out any accessories you get with the gun, and buy a nice rivet set. I prefer the flat set with a rubber ring around the edge to prevent the gun from running away. Also, go ahead and get a nice swivel whip tail.

5. You may still need a nice 2x or 3x gun, but for skins, this is the BEST.

You will see you get a really nice rivet gun for the small skin rivets with good control, easy to adjust and not driving them clear through to the other side of the wing with too strong of a gun. And the cost? under $10.

Rivet gun/Air hammer for skins

My rivet gun

Dkb