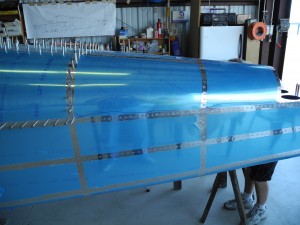

We have been making quite a bit of progress. Fuel pump is in, brake lines are inside, wiring movers forward, and the rear turtle desk is now riveted on. we wanted to be sure we did not have any more wiring to do before installing that. That area is now a tight fit if we need changes. Also, the seat belt shoulder harness restraint cables are in!

Many small tasks make it look like we have had little progress, but when you get a big piece on, it looks like you did a TON of work. Remember, the small stuff is important too.

The brake valve had to go back because the bottom fitting threads were wonky (an advanced aviation term) and will get a new fitting. I bought EZ Lube for all pipe thread fittings on brakes and fuel lines.