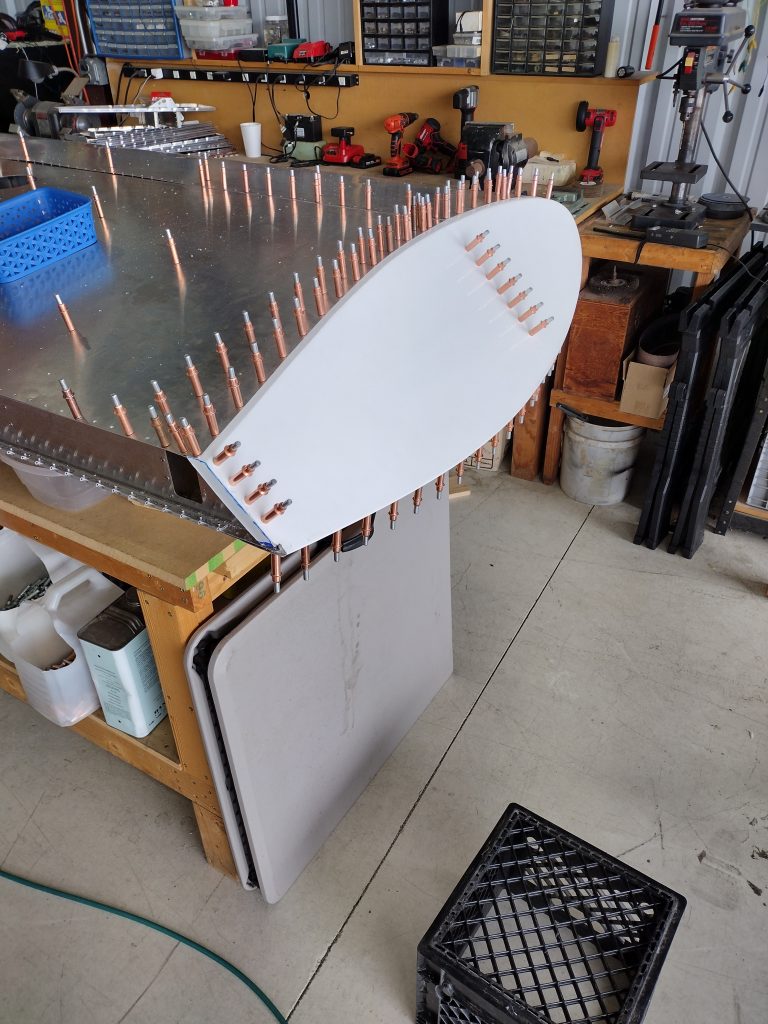

Well, I have to confess that I have ruined the flap. I incorrectly installed the flap hinge and not only is it crooked (too crooked to install the hinge pin) but it rises the flap into the wing in such a way that it will produce considerable drag.

Yikes!

Drilling out the hinges to try to reposition the hinge would create elongated holes that rivets would never set correctly.

This is my most expensive error yet.

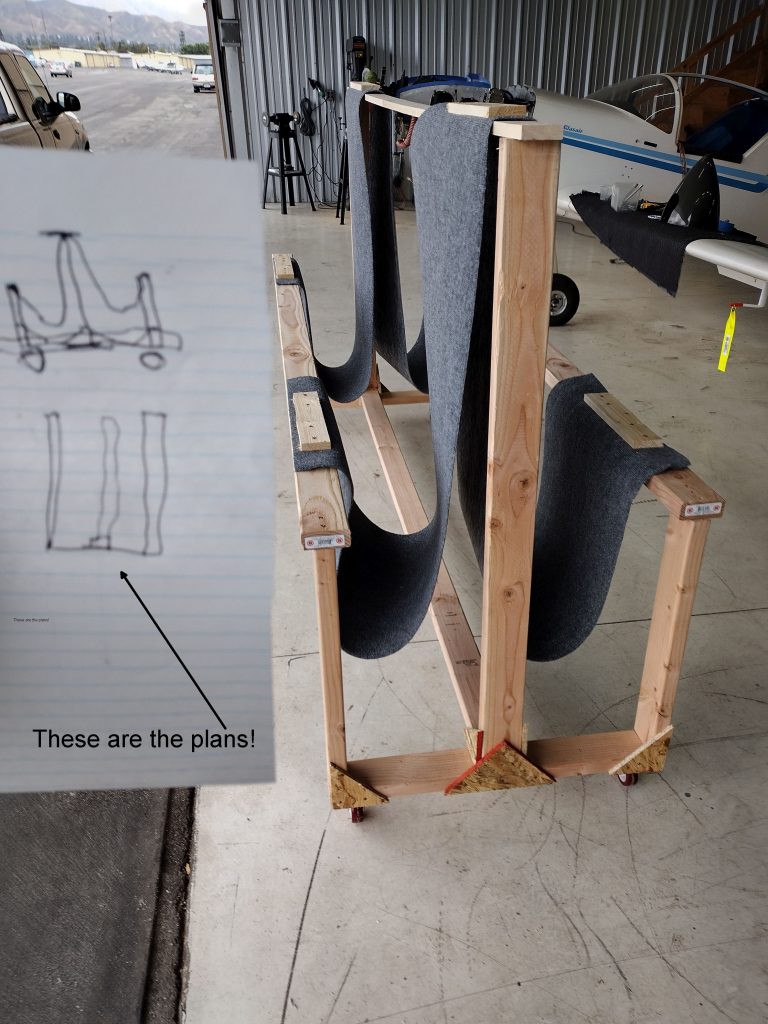

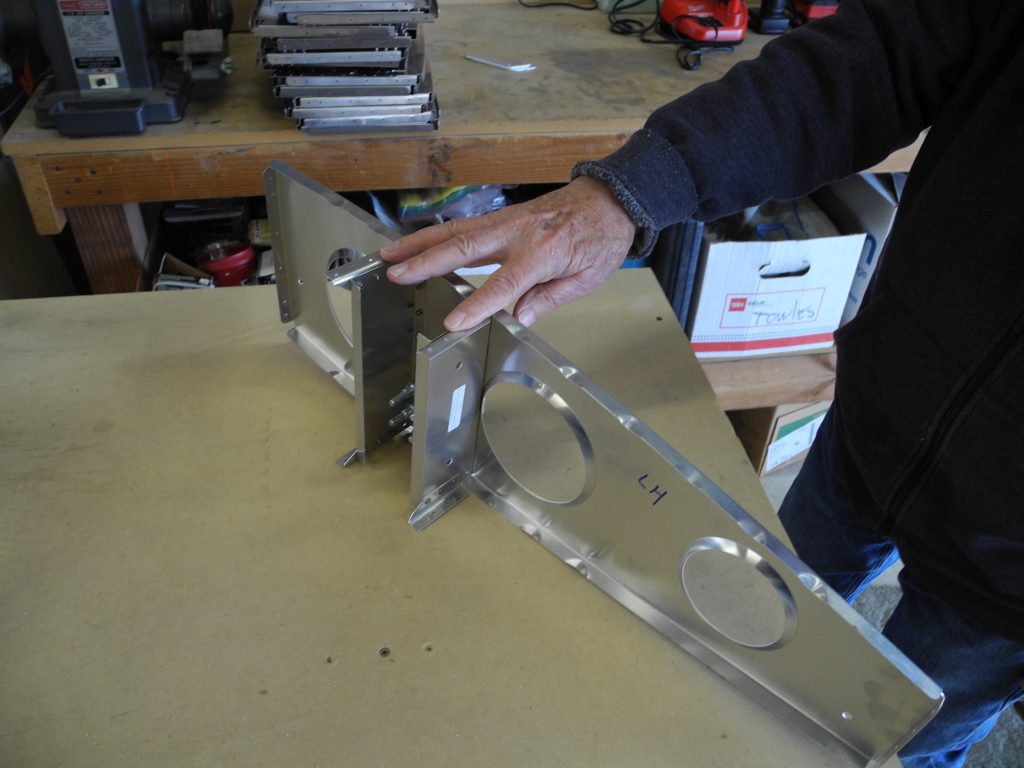

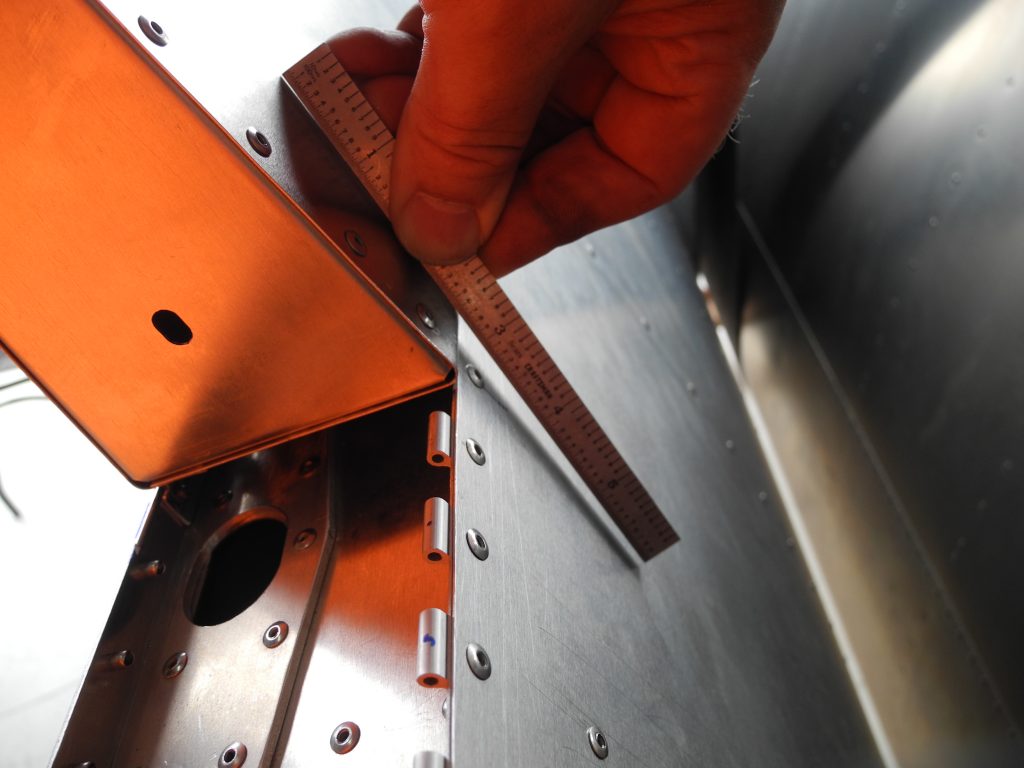

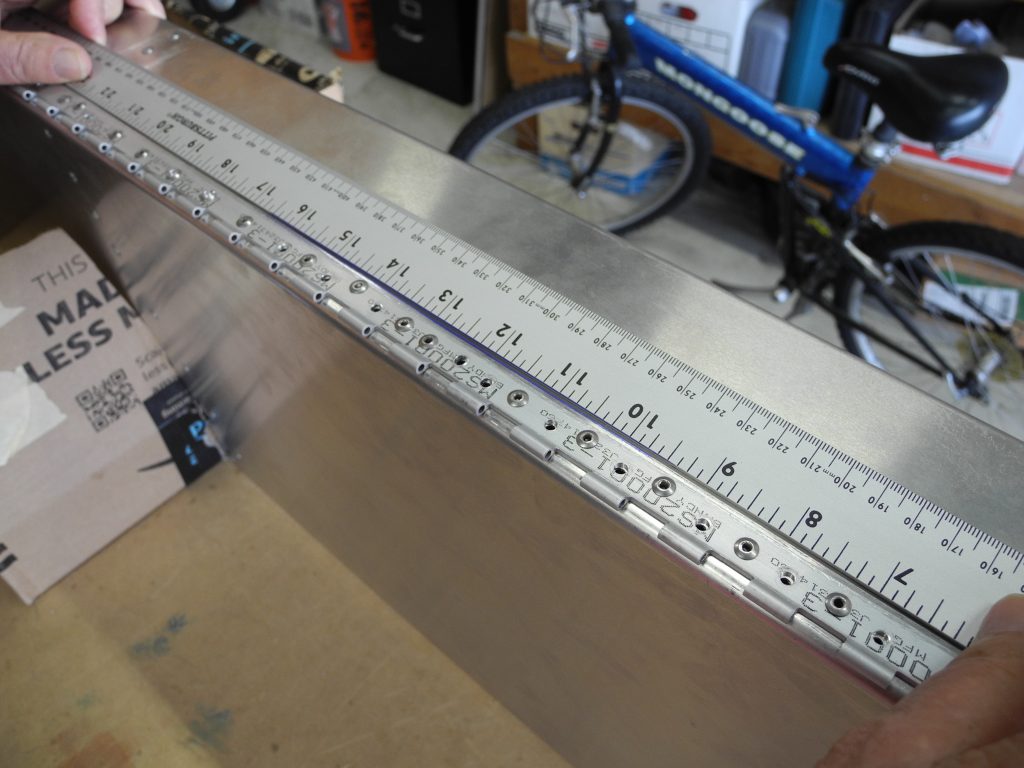

After a few back and forth emails with the mother ship, I got pictures of the correct way to position and space the hinge. Use a flat table, use a 1/16 ruler for spacing, apply weights to keep the flap flat, and drill holes with both flap hinges connected. I wish I had seen pictures of this process earlier.

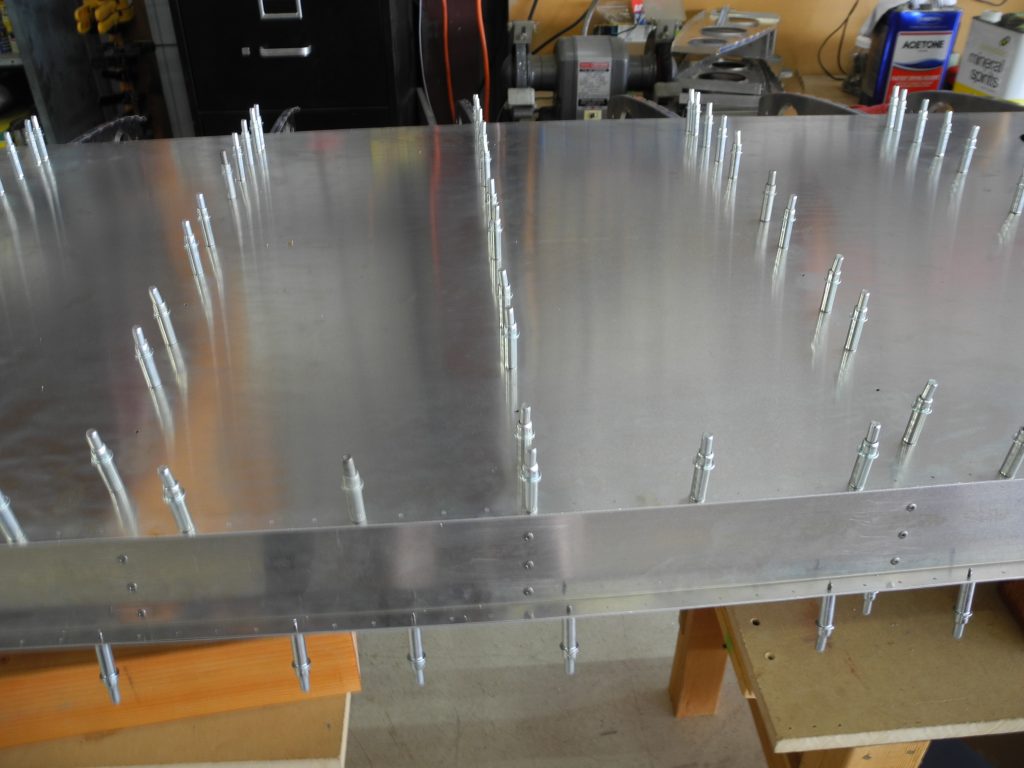

Since I ruined the flap anyway, I used the bad flap to experiment with the correct process. Too many holes to be safe, but with the new process, the hinge fit correctly.

Customer service was great, and the new parts for the flap shipped quickly.

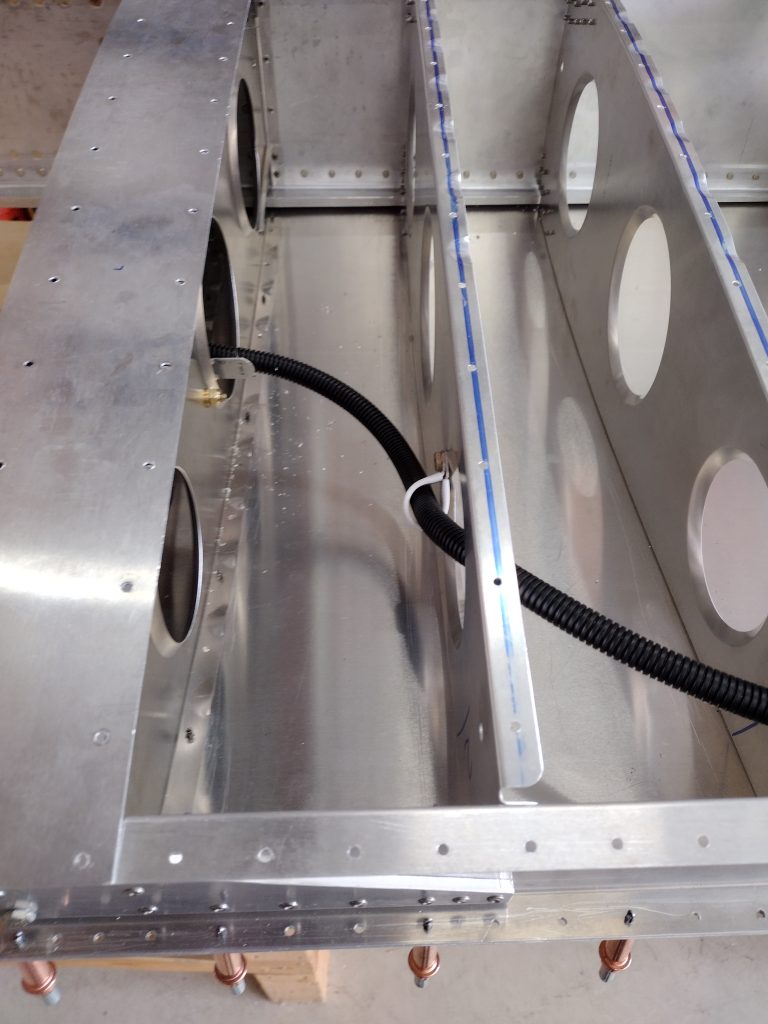

Flaps are done, and on to the ailerons. Actually, I have been working on both flaps and ailerons together. Lucky for me the goof in flap hinges did not occur with the ailerons.