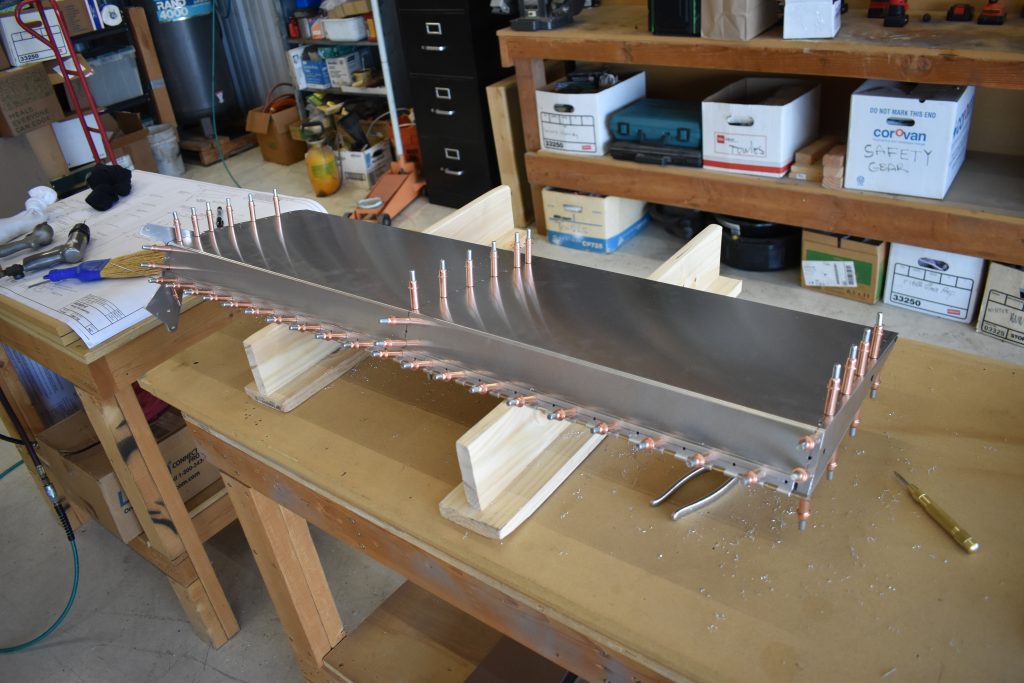

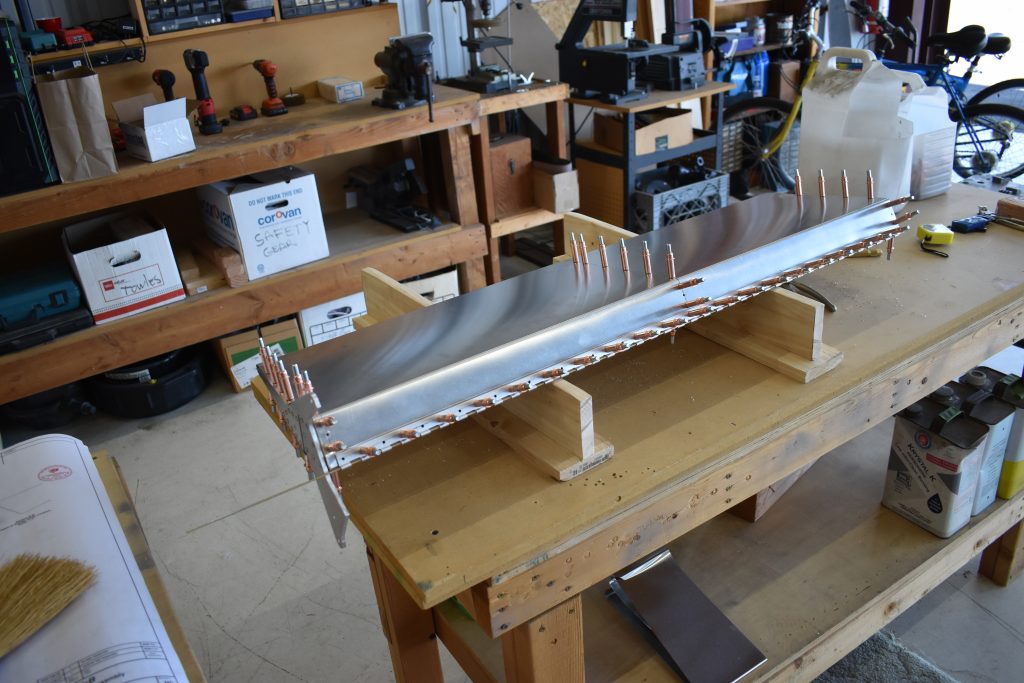

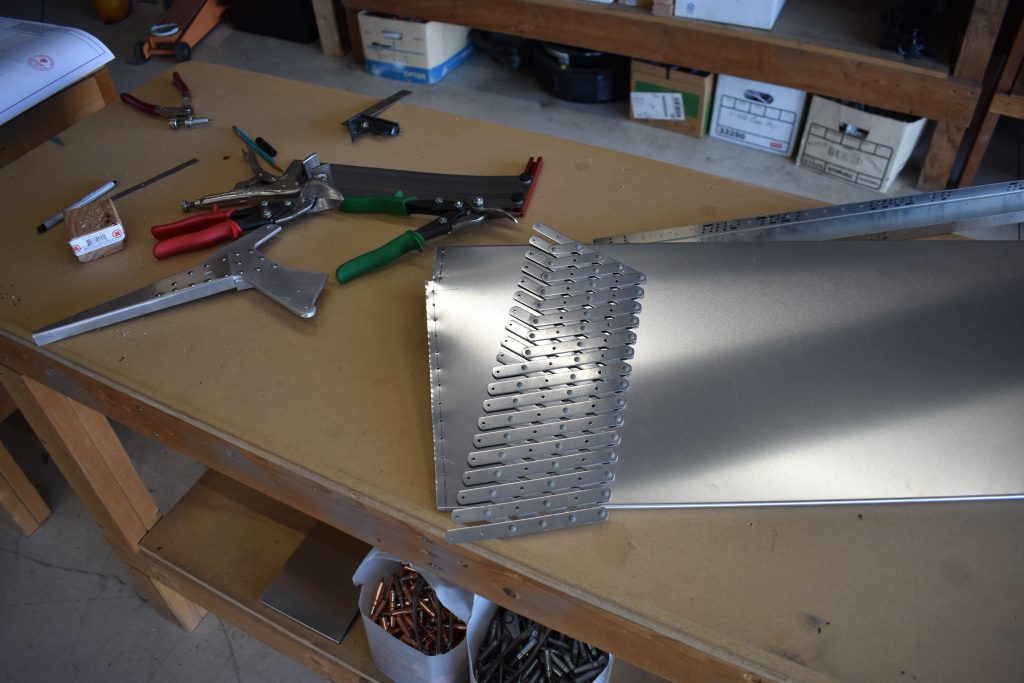

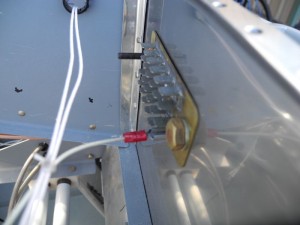

Built forward horizonal stabilizer spar today, and working on the elevators.

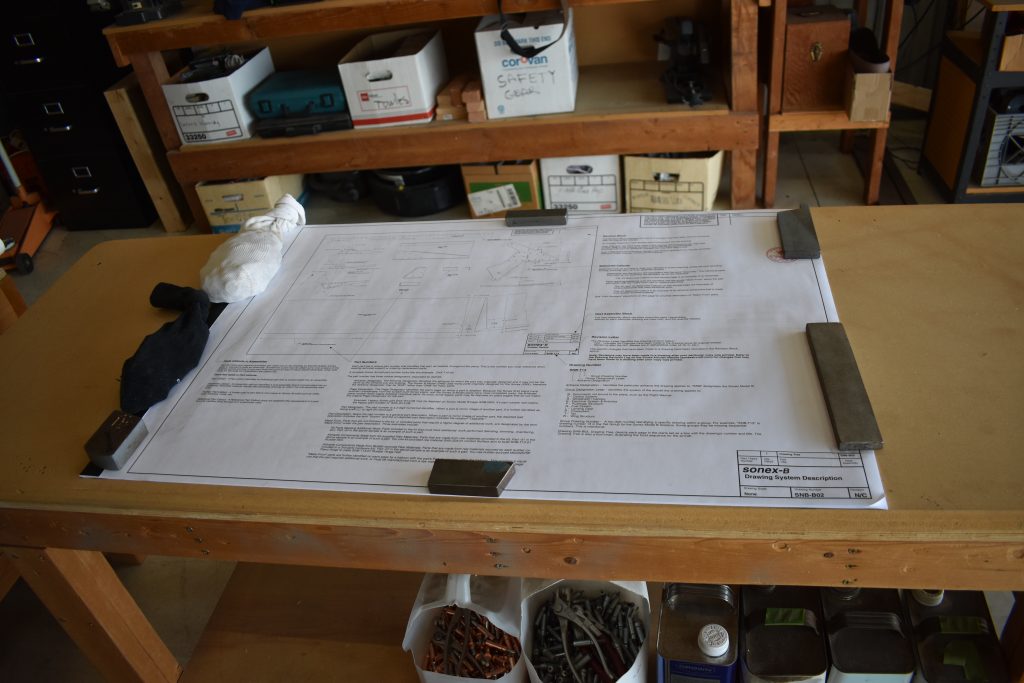

My airplane build is a collection of fear. What is the next fear? Then the next, etc. What happens if? what if I do the next thing out of order? What if? What if?

I do get over this, and when the next step is completed, all is good. Until the next fear.

My next fear? How do I build the elevator so it is perfectly straight? How do I make sure it is straight and properly connected to the horizonal stabilizer?

Many places to look from YouTube (lots of help there) as well as sonexbuilders.net.