It is the first day of spring and all is beautiful.

and extra beautiful because this guy is here.

So, XPO Logistics have arrived and I am at the airport (On Friday, my car didn’t make it as far as the airport, but that is another discussion. I said bad words).

I see 6 boxes. All in pretty good shape. Box 2 was kinda clobbered on the top, but contents are OK.

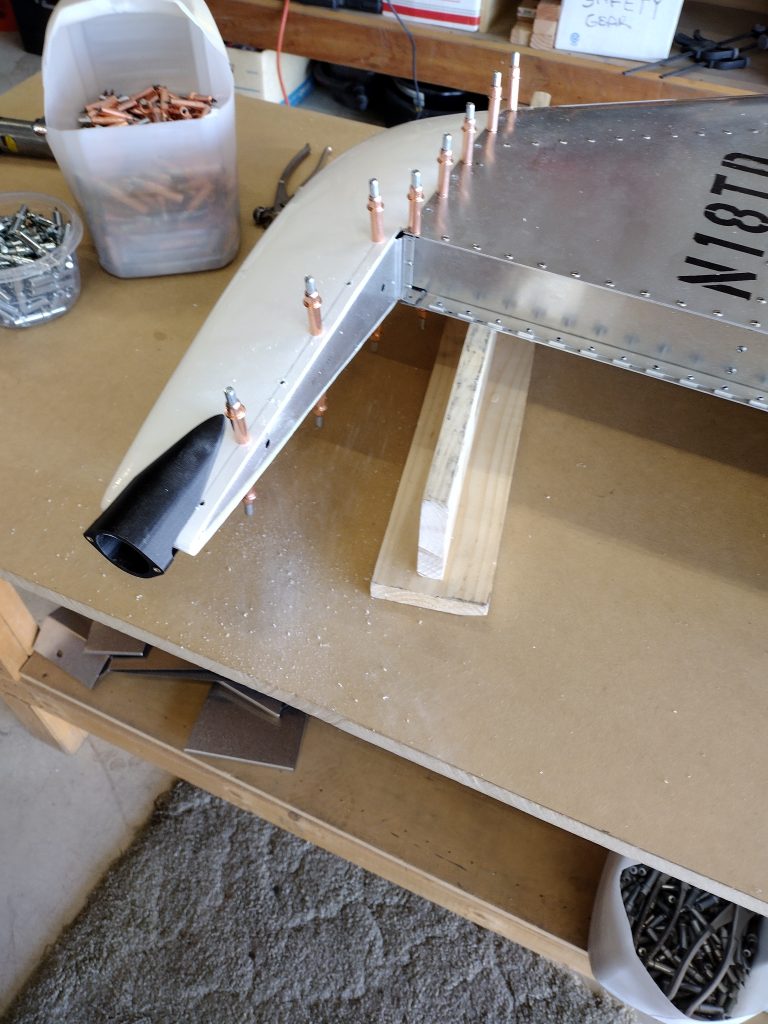

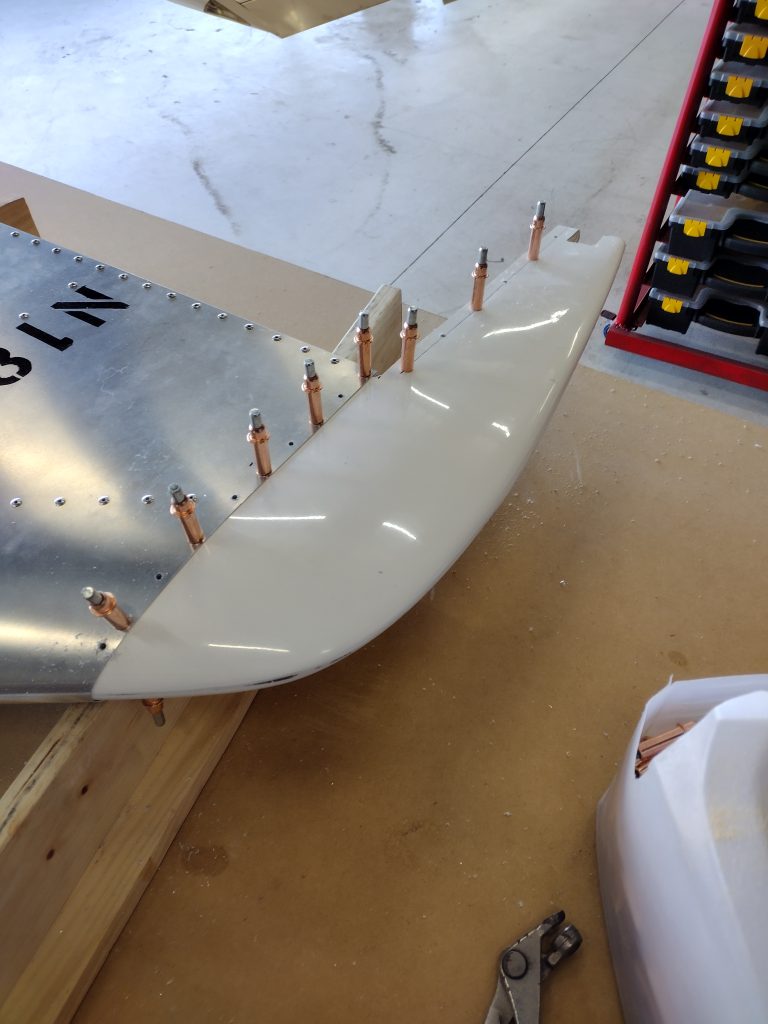

Some backorder stuff, but I’ll be able to get started with wings, no problem.

Does backorder stuff go to the airport or my house? I’ll email and find out.

We were able to unload the truck just as the Sonex website says, and all boxes fit in the hanger, and we waved good bye to the driver.

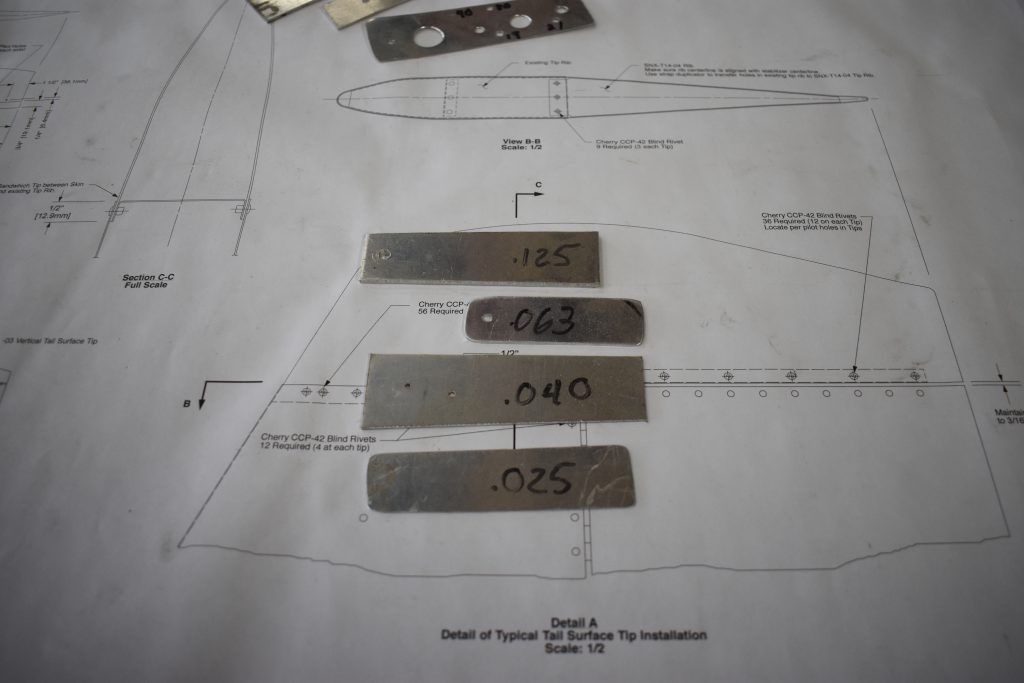

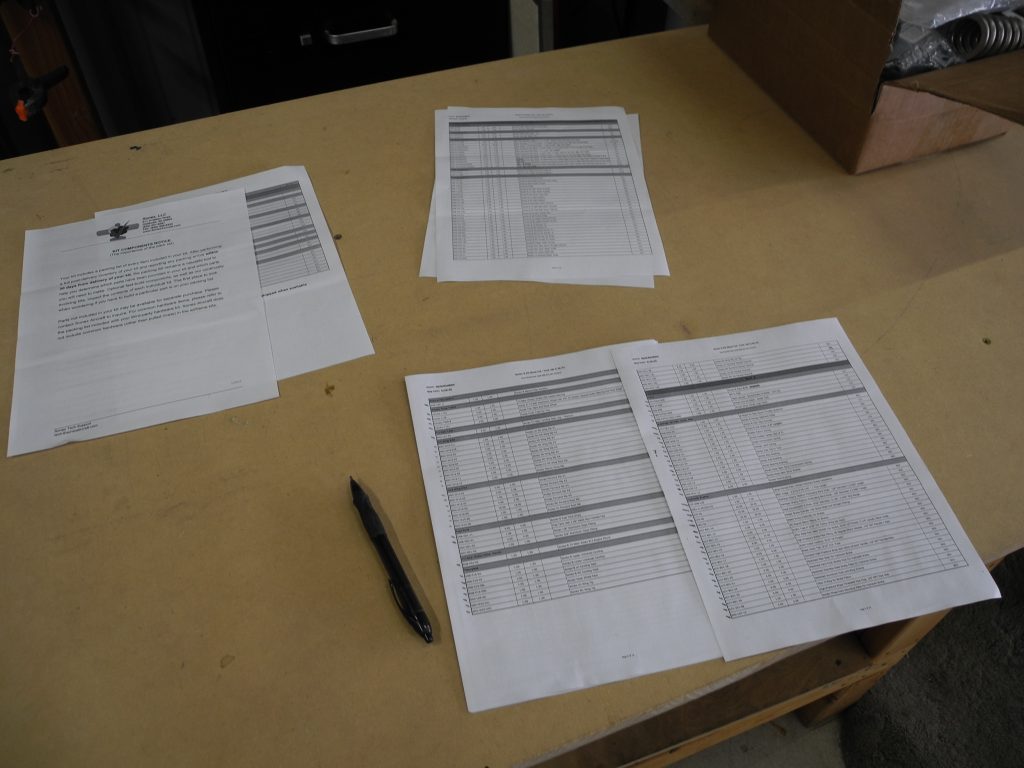

Immediately we are starting the inventory that will take a few days to complete. LOTS of stuff to count and review (Do I need 4 rudder cables?) What is a 1/8 oops?

Great job with packing.

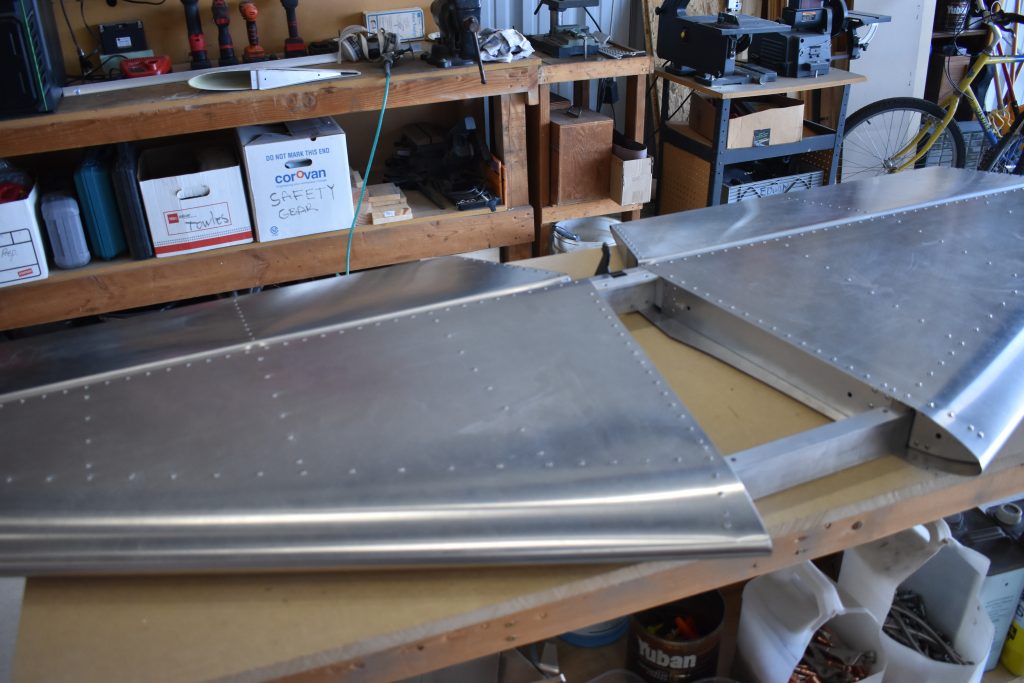

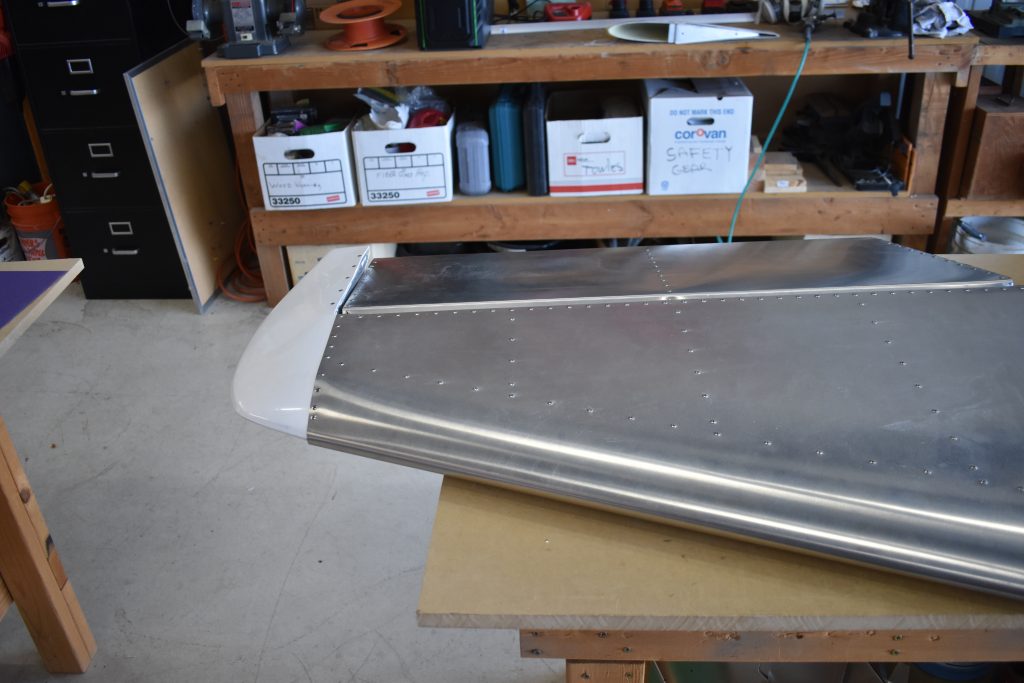

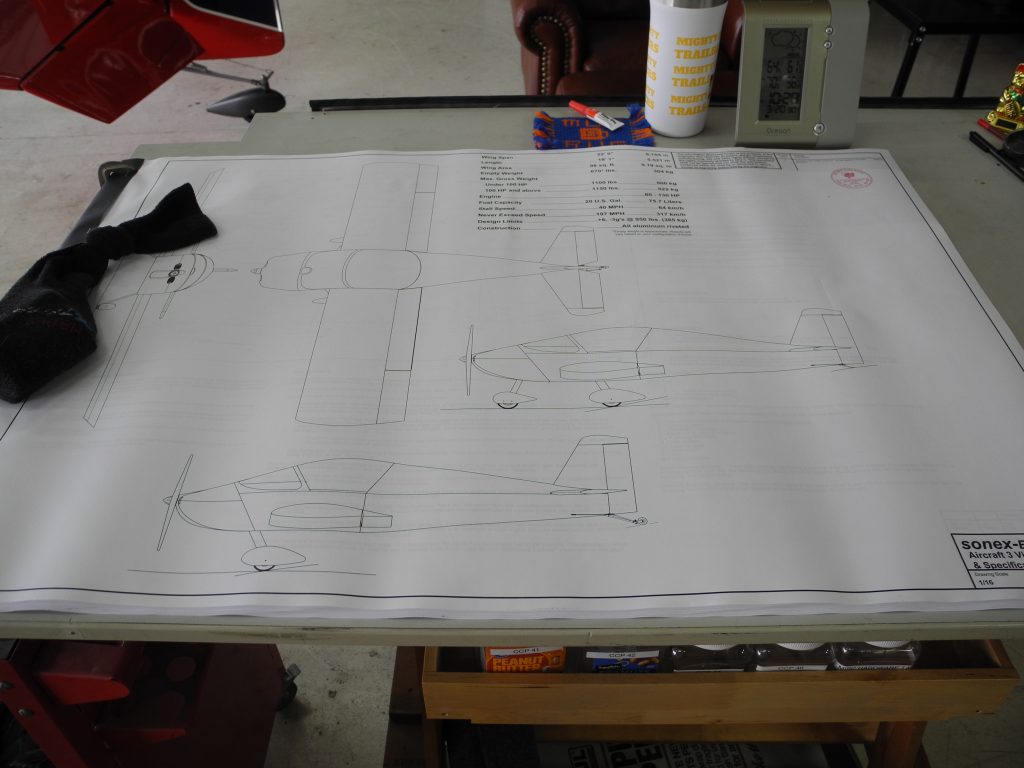

The plans are VERY intimidating. The entire airframe looks very complex. The Emp was easy, but this? Am I getting cold feet? Can I do this? So much to do.

And the plans! The plans are VERY intimidating. The entire airframe looks very complex. The empennage was easy, but this? These plans make War and Peace look like an evening read.

But then I remember. How do you eat an elephant?

One bite at a time.

Dkb