Today, Superbowl Sunday, Feb 3, 2013 is the 5 year anniversary of this project. As it just so happens, it was SuperBowl Sunday when we started as well.

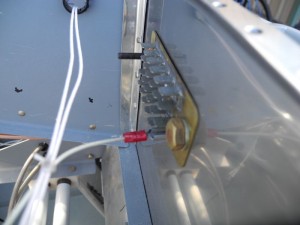

A lot of stuff has happened in 5 years. We completed the tail, wings, flight surfaces, gas tanks, much of the fuselage, installed the ELT and some wiring. Here is what we completed yesterday:

We have purchased an engine, the finish kit, and some of the firewall forward. Since we began, I have three new cats, a new car or two (we keep cars a long time) remodeled a bathroom, re-did the upstairs of the house, kept my job, learned a bunch of new skills, both with the airplane and at work, and stayed married. We have many new friends in the Van’s RV community, and have watched some speed past us, and some fall by the wayside.

We are planning flight instruments and radios. My Key: Keep it simple to start. 2 comms, 1 nav, 1 GPS external, and of course the GPS in the EFIS. We are still planning on Dynon Avionics, but we will simplify the panel to start. One EFIS for now. IFR VOR Nav configuration and maybe an IFR GPS. We will see about that. We have the transponder (King KT-76A) and the Audio panel.

Tom and I still love to build, and we are not about to rush to finish now. We have been very careful builders, and the work we have done is top notch!

So, When will the plane be finished? Not sure. Still much to do, but the next phase is to get the fuselage off the rotisserie and on a cart for setting the wings. Get the motor on and get the wiring done.

We’ll see.

Happy New Year!

Dkb